Ruthenium: Unearthing the Origins and Environmental Impact

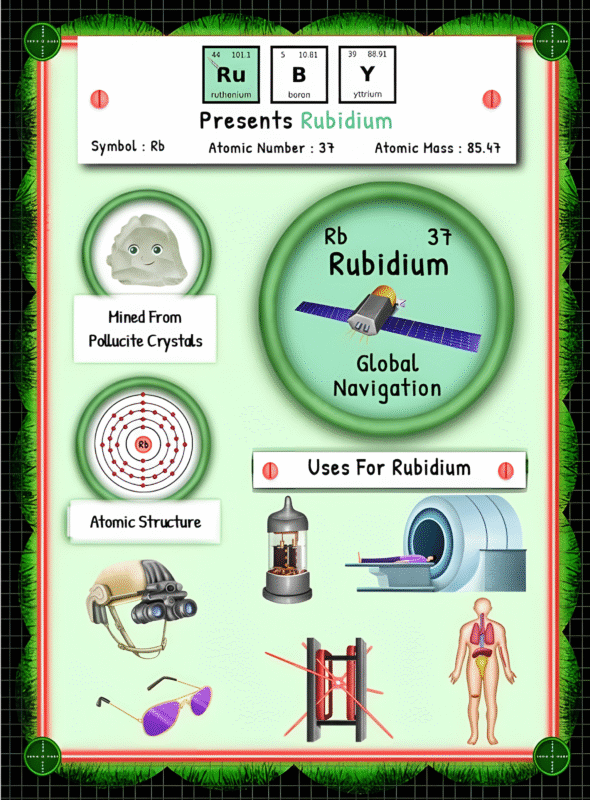

Ruthenium, a rare and precious metal, holds a fascinating history and serves numerous industrial applications. Discovered in the early 19th century, this element possesses unique properties that make it an essential component in various fields. In this article, we will delve into the origin of ruthenium, its extraction process, commercial processing, environmental impact, and the top mining and production countries.

Ruthenium does not occur naturally as a pure element. It is often found in association with other platinum group metals (PGMs) such as platinum, palladium, osmium, iridium, and rhodium. The most significant natural source of ruthenium is found in ores primarily mined in South Africa, Russia, and North America.

The mining process for ruthenium is intricate and demands expertise. It begins with the identification of suitable deposits, which contain ores with trace amounts of PGMs. Extracting ruthenium involves a series of complex steps including underground or open-pit mining, flotation, dewatering, and smelting. Once the ore is obtained, it is subjected to flotation where it is mixed with a reagent that attaches to valuable mineral particles and separates them from the non-valuable ones. The resulting concentrate is then dewatered and purified to eliminate impurities.

After the purification process, smelting comes into play. Ores are melted at high temperatures (up to 1,600 degrees Celsius) where PGMs like ruthenium separate from the other metals present. This separation step allows the recovery of ruthenium, along with other desired metals, as a by-product. While ruthenium mining involves complex processes, it effectively allows for the extraction of this valuable element.

Once ruthenium is extracted, the next stage involves commercial processing. The metal requires further refining to remove any remaining impurities. Electrolysis, a technique wherein an electric current is passed through a solution or molten substance, is primarily employed for the purification of ruthenium. This further increases its purity, making it more suitable for industrial uses.

Regarding the top mining countries, South Africa takes the lead. As one of the largest producers of PGMs, South Africa accounts for a significant portion of the world’s ruthenium supply. Its vast mineral reserves, particularly in the Bushveld Igneous Complex, serve as rich sources of ruthenium. In addition to South Africa, Russia and North America contribute to the global mining output of ruthenium.

However, the extensive mining activities associated with ruthenium extraction do have environmental implications. The mining process generates tailings, which are waste materials left over after the minerals are extracted. These tailings often contain harmful substances like sulfuric acid and heavy metals. Improper disposal or leakage of these tailings can lead to soil and water contamination, potentially harming the surrounding ecosystem.

Moreover, mining operations can disrupt the natural landscape, leading to deforestation and habitat loss for indigenous fauna and flora. These ecological disturbances can cause long-term harm, affecting biodiversity and the overall health of the environment.

In terms of commercial production, despite being a top mining country, South Africa does not commercially refine and process the majority of the ruthenium it mines. Instead, the majority of ruthenium refining is done in other countries such as Russia, Germany, and the United States. These countries possess advanced refining facilities and technologies, allowing them to process ruthenium to high levels of purity.

In conclusion, ruthenium, a valuable and rare metal, is primarily extracted from ores found in South Africa, Russia, and North America. Its mining process requires skilled expertise and involves intricate steps such as flotation and smelting. Although ruthenium does not exist in nature as a pure element, it is extensively used in various industries after commercial processing. South Africa, being a top mining country, mines a significant amount of ruthenium, while countries like Russia, Germany, and the United States perform the bulk of the refining and processing. However, the environmental impact of mining activities cannot be ignored, as they can lead to soil and water contamination, deforestation, and habitat loss. It is crucial for mining and refining practices to be conducted sustainably, with proper waste management and environmental considerations in order to mitigate these adverse effects.

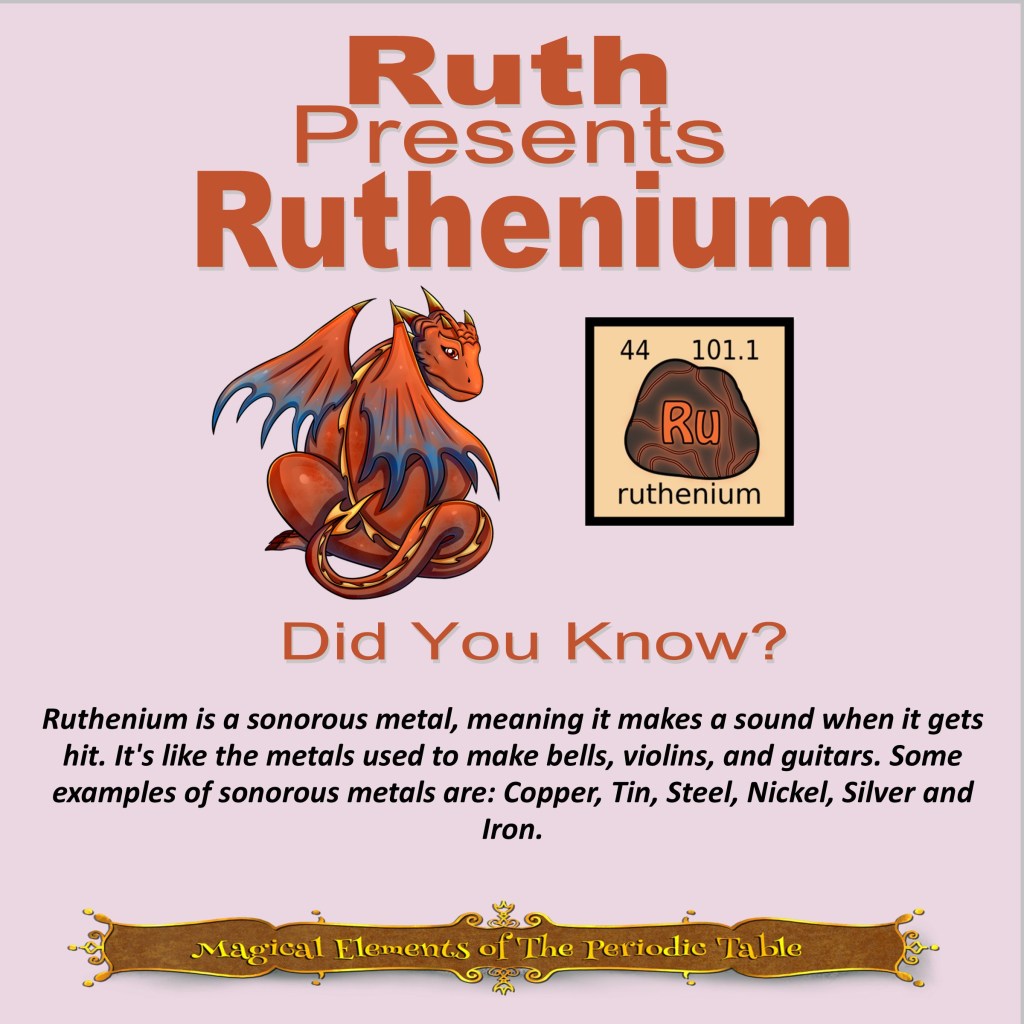

This article is brought to you by Sybrina Durant, the author of the middle grade picture book, Magical Elements of the Periodic Table Presented Alphabetically By The Elemental Dragons. Learn More. In that book Ruthenium is presented by the dragon, Ruth.

Inter-Active Elemental Fantasy-Themed Periodic Table from Magical Elements of the Periodic Table Presented Alphabetically by The Elemental Dragon Clan

Click here to use This Inter-Active Viewer To Learn More About The Elements Each Elemental Represents On This Periodic Table. Want this in a 24″ x 36″ Poster? Click here.

Sybrina Publishing Offers Fun Activities Based On The Book

Magical Elements of the Periodic Table Magical Elementals

Browse Magical Elemental Activities at MagicalPTElements or Sybrina-Publishing on TPT or Classful