The Origin of Magnesium: From Element to Commercial Production

Magnesium, a silvery-white metallic element, plays a vital role in various industries and everyday life applications. From aerospace to automotive, construction to healthcare, magnesium is highly valued for its lightness, strength, and corrosion resistance. But where does this essential element come from and how is it commercially processed? Let’s explore the origin of magnesium, its extraction process, commercial handling, as well as its impact on the environment.

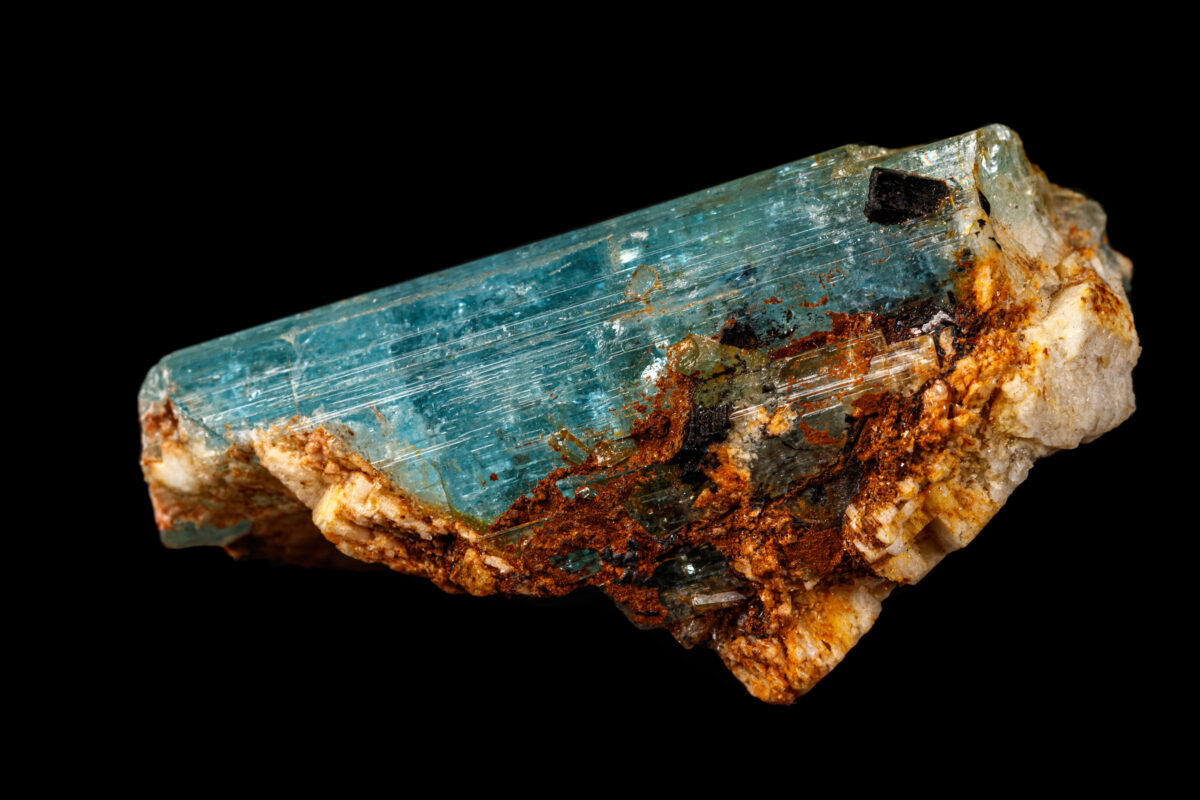

In the natural world, magnesium rarely occurs as a pure element due to its high reactivity. It is primarily found in combination with other elements. Magnesium comprises about 2.4% of the Earth’s crust, making it the eighth most abundant element. The most common minerals containing magnesium are dolomite, magnesite, and carnallite. Magnesium also exists in seawater, with the concentration around 0.13%.

To extract magnesium from its natural sources, mining is required. The mining process varies depending on the ore type. Magnesium can be obtained through two primary methods: thermal reduction and electrolysis. The thermal reduction method is typically used for the extraction of magnesium from dolomite and magnesite.

In the thermal reduction process, the ore is first heated to produce magnesium oxide, or magnesia. This initial step involves heating the raw material in a furnace at a temperature of around 900℃ (1650℉), causing the magnesium carbonate to decompose and release carbon dioxide gas. The resulting magnesium oxide is then further processed and reduced using a furnace or a reactor with ferrosilicon or ferrosilicon alloy, resulting in the production of magnesium.

Electrolysis, on the other hand, is the primary method employed to extract magnesium from seawater and brine. Seawater contains an abundance of dissolved magnesium chloride, which can be extracted using specialized electrodes and an electrical current. This process is known as the Dow’s Magnesium Electrolysis Process and was developed by the Dow Chemical Company in the early 20th century.

Once extracted, magnesium goes through several commercial processing steps to ensure its purity and suitability for various applications. The first step is typically refining, where impurities are removed from the extracted magnesium. This is achieved by treating the crude magnesium with chlorine gas or sulfur dioxide in a high-temperature furnace.

After refining, further processing may occur depending on the desired final form of the magnesium. For example, if magnesium alloy production is the aim, additional alloying elements such as aluminum, zinc, and manganese may be added during melting and casting processes. These alloys provide enhanced strength and specific properties for various industrial applications.

China is the world’s leading producer of magnesium, accounting for approximately 80% of the global production. The country has extensive magnesite deposits, particularly in the provinces of Liaoning, Shaanxi, and Shanxi. While the high production volume has contributed to China’s economic growth and international trade, it has also raised concerns about the environmental impact.

Magnesite mining can have severe consequences on the environment. The extraction process involves strip mining, which removes vegetation and topsoil, displaces wildlife, and leads to soil erosion. Additionally, the release of dust and chemicals during mining activities can contaminate nearby water sources, affecting aquatic life and human populations.

Environmental concerns have led to increased regulations and efforts to mitigate the impact of magnesite mining. Government intervention, reclamation programs, and improved technologies are being implemented to ensure responsible mining practices and reduce the negative ecological footprint.

In terms of commercial production, China also dominates the market, followed by Russia and the United States. The high demand for magnesium in automotive, aerospace, and electronic industries has driven the need for increased production. However, other countries such as Canada, Israel, and Brazil also contribute significantly to global magnesium production.

In conclusion, magnesium, a versatile and valuable metal, is primarily extracted from minerals like dolomite and magnesite or from seawater and brine. The mining process involves thermal reduction or electrolysis, followed by commercial refining, alloying, and processing. China leads in both magnesium mining and commercial production, raising concerns about its environmental impact. Nonetheless, efforts are being made globally to ensure responsible mining practices and mitigate the ecological footprint associated with magnesium extraction.

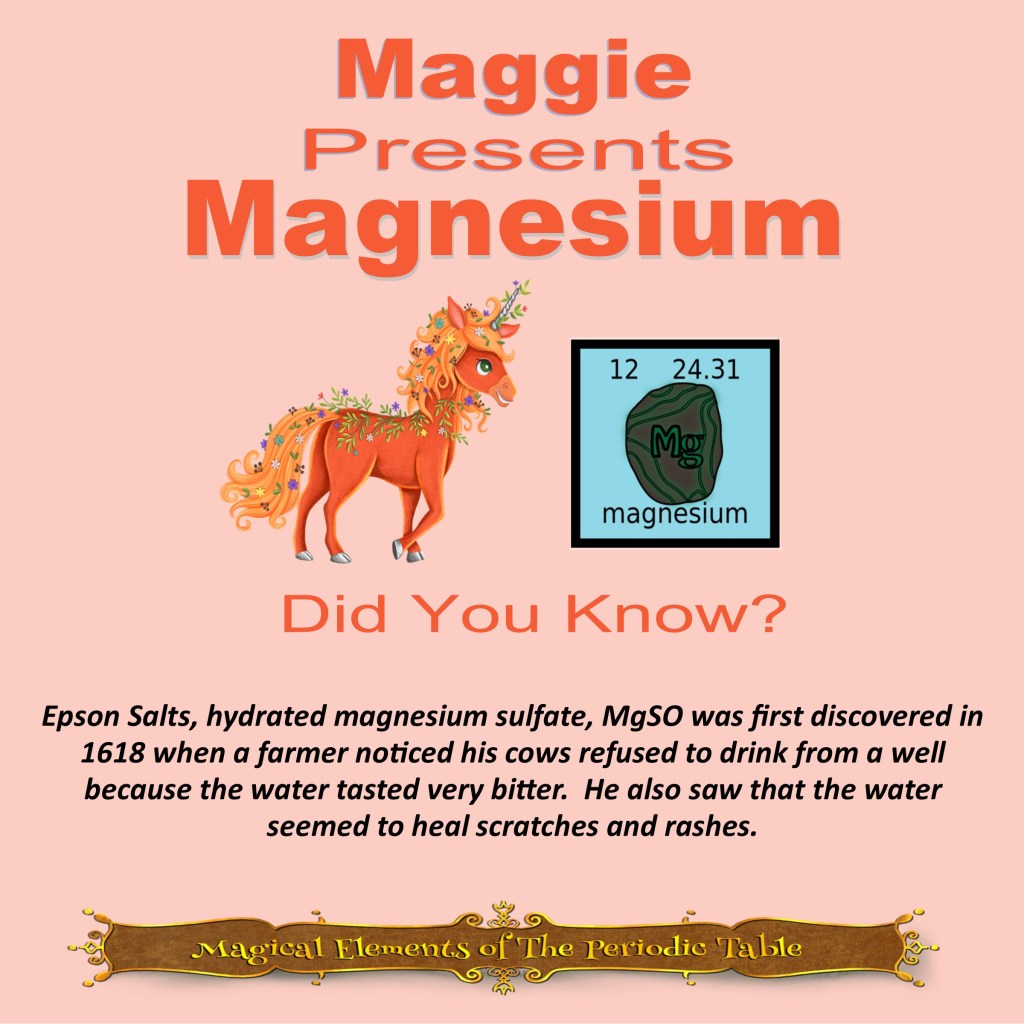

This article is brought to you by Sybrina Durant, the author of the middle grade picture book, Magical Elements of the Periodic Table Presented Alphabetically By The Metal Horn Unicorns. Learn More. In that book Magnesium is presented by the unicorn, Maggie.

Inter-Active Elemental Fantasy-Themed Periodic Table from Magical Elements of the Periodic Table Presented By The Magical Elementals

Click here to use This Inter-Active Viewer To Learn More About The Elements Each Elemental Represents On This Periodic Table. Want this in a 24″ x 36″ Poster? Click here.

Sybrina Publishing Offers Fun Activities Based On The Book

Magical Elements of the Periodic Table Magical Elementals

Browse Magical Elemental Activities at MagicalPTElements or Sybrina-Publishing on TPT or Classful